The Engineering Department is pleased to announce our annual year-end student awards. This list of awardees represents just the tip of the iceberg of the amazing engineering students at Hope College. Descriptions of the awards and some information about the recipients are give below.

Clara Voskuil and Dylan Clem were selected by the engineering faculty to receive the Senior Engineering Prize. This award is given to the senior student who is the most outstanding student in engineering. While at Hope College, Clara was involved in Greek Life, intramural sports, and student orientation. She participated in several study abroad opportunities, including the first Engineering Summer Program in Germany. She was also a research student in Dr. Peckens’ lab and completed a second major in math. She will be working for Walker Consultants as a Structural Restoration Engineering in Ann Arbor.

While at Hope College, Dylan was involved in Football, including being captain of the team two times, was a member of Athletes Coming Together / Student-Athlete Advisory Committee, and was part of the athletic mentoring program, Team 43. Dylan was also a research student in Dr. Peckens’ lab and completed a minor in math. After graduation, Dylan plans on obtaining a job as a structural engineer.

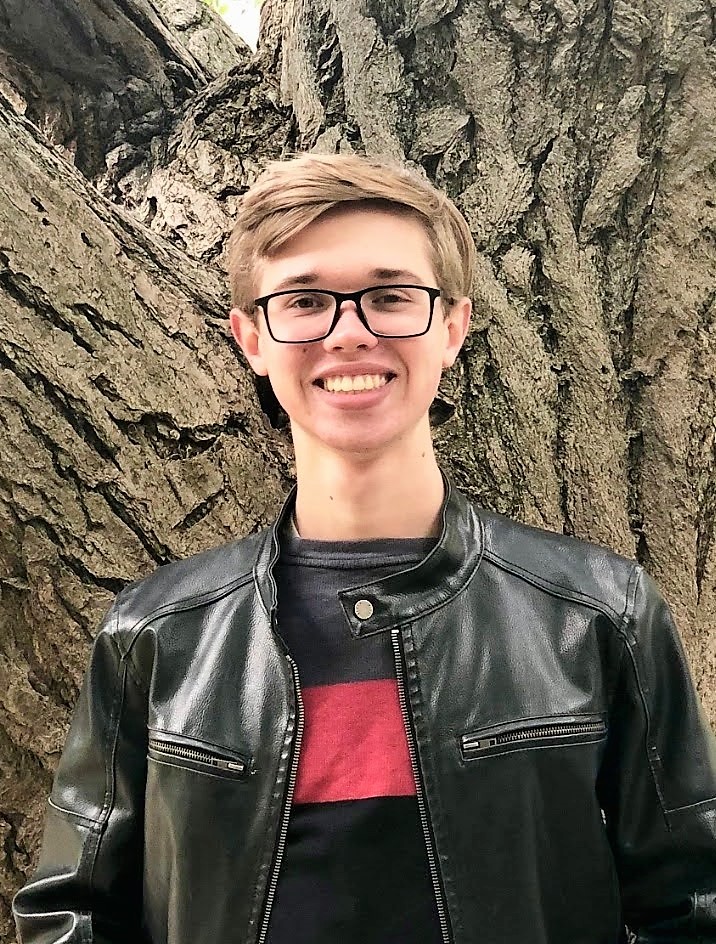

The VanPutten Prize is given by the Engineering faculty to a graduating engineering student who shows exceptional ability, interest, and accomplishment in engineering design. This award is named in honor of Professor James VanPutten in recognition of his accomplishments in engineering design and his efforts to establish the engineering program at Hope College. This year’s recipients is Parker Bos. Parker’s senior design project was sponsored by the company at which he was interning and where he will be working full-time after graduation, Mission Design and Automation. The project resulted in a robotic arm that interfaced with users to play roulette. While at Hope, Parker was a member of the Arcadian Fraternity and was part of the fly fishing club. In addition to his degree in engineering with a mechanical concentration, he also obtained a minor in math.

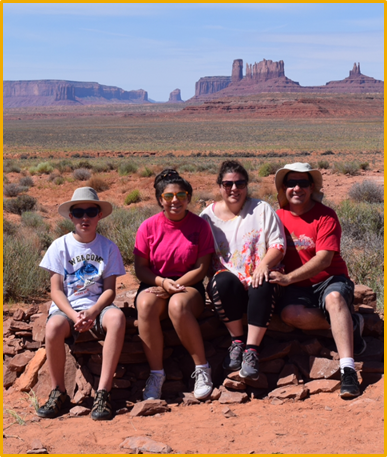

Rory Campagna received the Blok-Williams Graduate Student Award award, which is given to a graduating senior student who has demonstrated outstanding excellence in engineering studies and is bound for graduate school. This award acknowledges the recipient’s exceptional achievements, commitment to academic excellence, and potential for advancing the field of engineering. It serves as a notable accolade, honoring the recipient’s remarkable contributions to the engineering community and inspiring their future endeavors in graduate studies. While at Hope College, Rory worked in Dr. Christian’s research lab and held an internship at Sherwin Williams aerosol plant. He also was involved in IM sports, the spikeball club, and was a teaching assistant for Chemistry. In additional to his major in Engineering with a Chemical concentration, he also majored in Chemistry. This fall he will be pursuing his master’s degree at Penn State in Food Science and plan on going into an R&D position in the food industry.

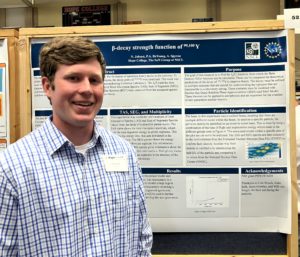

The selection of the Paul Baeverstad Award recipient is based on a vote of the senior class of engineering students. It is given in recognition of a student who is valued as a superior engineer, classmate, and friend. This year’s winner was Nate Jobson. While at Hope, Nate worked on research in the Physics department for two years and in addition to his major in engineering, he also completed a major in Physics. He also played lacrosse for four years and served as the president of the pickleball club. This fall he will attend Worcester Polytechnic Institute to pursue a PhD in applied physics.

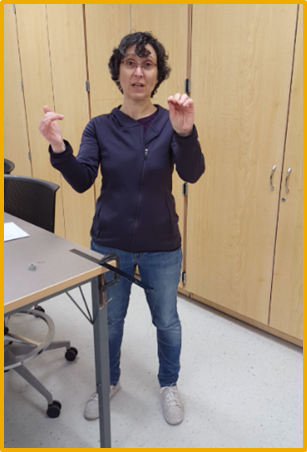

The Freshman Engineering Prize recognizes outstanding first-year engineering students who have demonstrated academic excellence and a strong commitment to the engineering community through leadership, initiative, and dedication in their studies and extracurricular activities. The award aims to encourage and inspire students to strive for excellence and become active members of the engineering profession. The two students to receive the award this year were Avery Almy and Ainsley VandenBrink. When asked about what he enjoyed most about Hope during his first year, Avery said, “I enjoyed making friends, goofing around, and learning more about subject matters I’ve been interested in for a long time with professors who care about me and want to see me succeed. I’ve enjoyed being more than a number and feeling like I belong here.”

Ainsley’s response was, “What I enjoyed most about my freshman year of college was the opportunity to immerse myself in my academic endeavors through various courses and research, delving into subjects that fascinated me. Additionally, the dynamic blend of challenging courses and the supportive relationships formed with professors and peers truly enriched my learning experience.”